When it comes to garment production, fabric is one of the most crucial elements. Without the right fabric, factory cannot proceed with manufacturing. This is especially true in the early stages of developing a new collection. Most of the time during the development process is spent on fabric sourcing and selection. So, should you handle fabric sourcing yourself or leave it to your factory?

The Challenge of Too Many Fabric Choices

Usually, factory can assist with fabric sourcing. You provide the type of fabric you need, perhaps with inspiration images or specifics about fabric composition. However, these details only gives a rough idea of what’s needed. With thousands of fabric options available, narrowing down the right one can be tricky. Fabric is varied from its thickness, weight, composition and prices. If you cannot provide a physical sample or fabric cutting to follow, it is hard for the manufacturers to pinpoint exactly what is asking for, especially during initial collaborations.

The sourcing process takes 7–15 days per round, and if the first batch of swatches doesn’t meet your expectations, the cycle repeats. This timeframe can extend further when there are many different styles involved.

Until the fabric is confirmed, no further progress can be made. The factory cannot proceed with the next steps, such as creating patterns. Usually, when making patterns, it also needs to refer to the fabric to be used on the style to consider on the measurement, things like that. Factories typically prefer to complete all the styles for a single client at once to avoid confusion for the workers, as different clients have different requirement. If only 1-2 fabrics are confirmed out of 20 styles, the factory will wait until the remaining fabrics are confirmed before moving forward.

The Tendency to Choose Easier Tasks First

Factories are certainly capable of sourcing fabrics, and many clients rely on them for this task. However, there are limitations to this approach. Factories tend to prioritize tasks that are easier to execute, and fabric sourcing can fall to the bottom of their to-do list if the requirements are unclear.

It is a natural human tendency to choose the less complex or more straightforward work and postpone the more challenging tasks for later. The clearer the fabric you are looking for, the faster factory response to. For instance, if you could provide a piece of fabric or garment sample and ask them to find a same or similar one, it is easier for them to tell you needs and they can find out the options for you very quick. However, if you only tell you want a “soft cotton fabric,” that leaves them with millions of options to choose from.

I worked with a client who had already chosen the fabrics for their entire collection. They simply provided the manufacturer with the fabric supplier’s contact details listed on the tech packs. This allowed the factory to purchase the fabrics right after they receive the tech packs. Pattern- making can be started at the same time. Once the fabric was received, cutting and sewing could begin immediately. This approach allowed us to complete 60-70 new styles within 18 days.

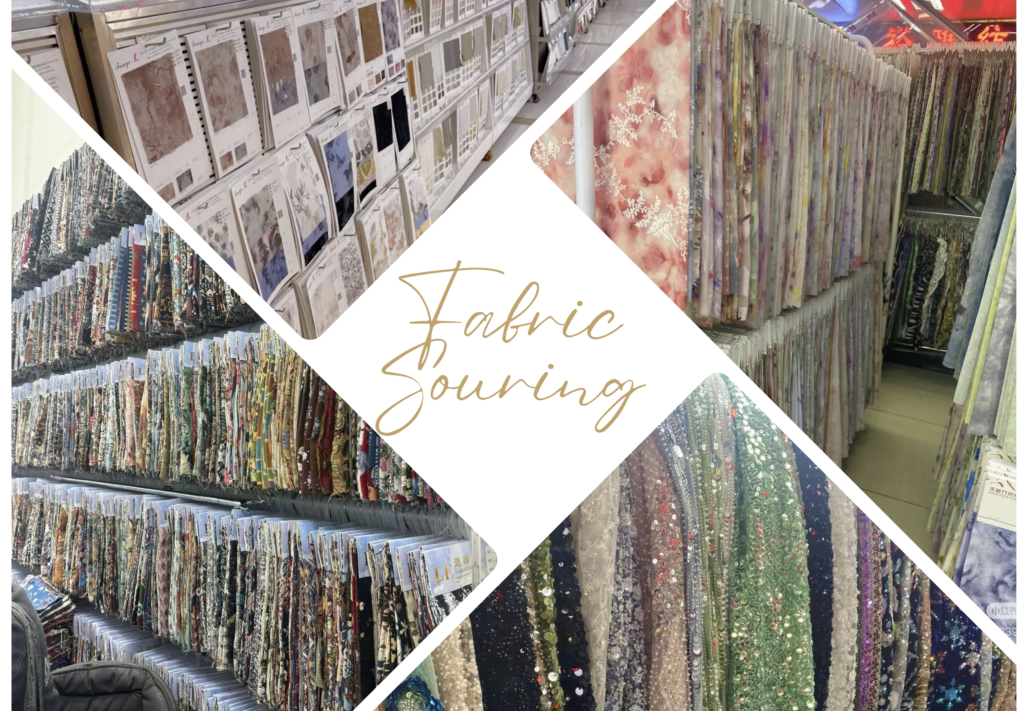

This client have the fabric sourced by a local coordinator in China who sourced fabrics from the Zhongda fabric market early in the development process. By sending swatch cards to the client, the designer could make fabric selections from those options. With long term co working, the a local coordinator had a clearer understanding of fabric options and costs his employer needed. Then he can find options more efficient and correctly. To the manufacturer, they save quite a lot time and just focus on develop the samples and production.

Source Fabric Yourself or Hiring A Local Assistant

Faster Turnaround Times

Since factory is capable of sourcing fabric on your behalf, why bother to source fabric by yourselve? While it’s not absolutely essential to hire someone to source fabric, there are some advantages to handling it yourself. I have clients who, every year, every collection, send their designers to come to the Zhongda fabric market in China to personally source fabrics for their new collections. Even after the COVID-19 pandemic made travel difficult, a client opted to hire local individuals to source fabrics on their behalf, and continued with this practice post-pandemic.

When you source fabrics independently, you’re not dependent on the factory’s schedule. This can significantly speed up the development process, especially if you’re working on a tight timeline.

Better Alignment with Your Vision

Sourcing fabric personally gives you a clearer idea of what you want. You can select fabrics according to specific requirements and budget, speeding up the process. On the other hand, when relying on the factory to source fabric, it may take multiple attempts to get the right material, especially if they misunderstand your preferences.

Cost Transparency

By sourcing fabric yourself, you have a direct understanding of the material costs. This can help you better control the overall production budget. During the pricing discussion with the manufacturer, you have more control at least on the fabric costing.

Role of Having a Local Coordinator

If traveling to fabric markets isn’t feasible, a local coordinator can be invaluable. They serve as your eyes and ears on the ground and can leverage local knowledge to source fabrics more efficiently (and potentially at lower costs).

Language barriers can often create challenges in international communication. When you has a local order coordinator, it helps bridge this communication gap. The coordinator can act as an intermediary between you and manufacturer, ensuring that the manufacturer fully understands your needs and preferences.

From the factory’s perspective, foreign clients who have a local order coordinator are seen as more reliable and trustworthy. This trust is crucial, as it helps build a stronger working relationship and facilitates better collaboration throughout the production process.

What’s your experience with fabric sourcing? Have you handled it yourself, or do you rely on your factory? Share your thoughts in the comments below.

If you’re looking for help sourcing fabric for your next collection, I can assist you in finding the fabric swatches and send them directly to you. Each swatch includes the contact details of the fabric suppliers, allowing you to reach out directly or pass the information along to your manufacturer.

You may also be interested in this post. A Guide to the Super Fabric Market in Guangzhou, China