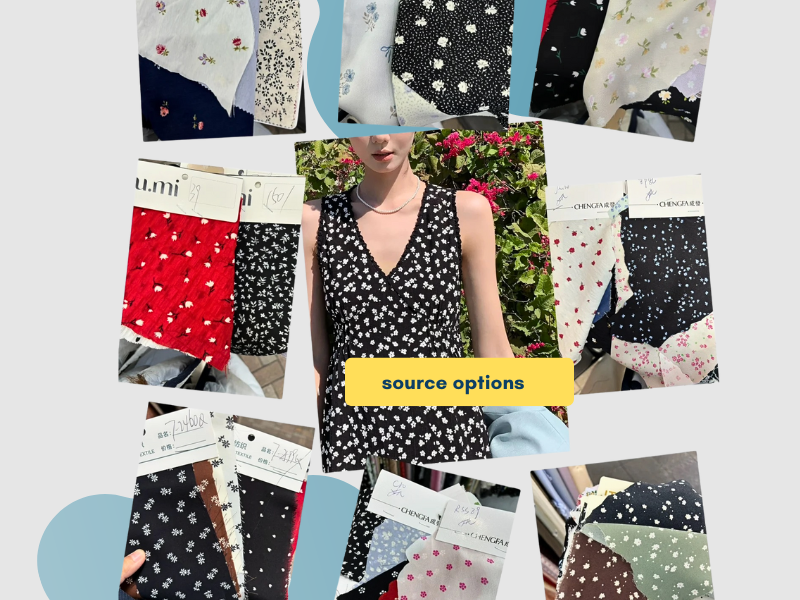

I often receive requests to help clients source fabrics from China, though fabrics are far from the only products I can help with.

Compared to other products, fabric is uniquely challenging. A photo simply can’t capture the texture, thickness, stretch, fiber content, or drape.

In this post, I’ll share a recent experience: how I helped a client source several fabric based on the small fabric swatches they sent me. And completed the sourcing and ordering in 5 days, and ship the goods to them.

Table of Contents

Step 1: Fabric Swatches: The Smartest Way to Start

To help the client find the right fabric, I suggested that them mail me the fabric cutting/swatches. That made everything much easier and faster. With the swatches in hand, we could see and feel the fabric’s weight, texture, and structure directly, and compare it to options in the market.

As soon as I received it, I headed straight to Zhongda Fabric Market in Guangzhou to begin the search.

Step 2: Two Days in the Market Sourcing and Collecting Options

I spent two full days walking through suppliers who specialized in those fabric category, comparing the swatch with available fabrics. Some were similar in look but differed in thickness, stretch, or finish, more or less stretchy, heavier or lighter, smoother or rougher.

For each one that was a potential match, I:

- Asked for a color card or fabric cutting sample if swatch card was not available

- Wrote down the fabric price directly on the swatch card

- Asked suppliers to list any shortage, which affects real fabric cost and make sure ordering enough quantity

After collecting all the possible options, I sent the client photos and videos for initial review. Once they narrowed down their choices, I mailed them the swatches.

Step 3: Quick Decision-Making in 1 Day

When my client received the fabric options, they spent 1 day going through them and confirmed and sent me all the options that he would like to order, including specific colors and quantities. He sent me via WhatsApp messages.

I then organized everything into a clear Excel sheet, listing the fabric codes, images, color number, prices, quantities, and total cost. This helped avoid miscommunication and made future follow-up much easier.

Step 4: 1 Days for Fabric Availability Checks

Here’s something important: in fabric markets, when you casually ask if a fabric is “in stock,” most suppliers will say yes, even before checking.

They manage hundreds of fabrics and colorways, and stock is often kept offsite. Real inventory checks usually only happen after you confirm color and quantity. It usually take some time to get answer whether in stock or not, or how many they have. It happens that you would be informed that the fabric is out of stock after you place order 1-2 days.

Step 5: 1 Day for Order Placement and Payments

According to the confirmed order list, I contacted the suppliers one by one. Let them know which fabric code/color/quantity I need, then they proceeded to check with their warehouse. Some responded within an hour. Others took nearly a full day. Since fabric is pre-rolled, and each roll varies slightly in meter count. Suppliers usually provide the closes meters quantity you need. It would not be exact same quantity you need. The total amount may be more or less, like 10-30 meters or so. I listed out the available roll counts and quantity in details so the client could decide which to proceed with. I then placed orders one by one.

When all the details were confirmed, my client just wired the full payment to me and let me handle to pay the suppliers.

Some fabrics were ready for pickup in 1-2 days and required full payment upfront. Others needed a few more days to be finished, so we paid a deposit first and settled the rest upon pickup.

Step 6: Quality Control — No Surprises Allowed

Since these fabrics were being exported to my client’s country, we couldn’t afford issues upon delivery. It’s costly and frustrating for the client if the wrong fabric or a defective roll shows up at their side weeks later.

So before placing orders, I clearly explained the quality matters to each supplier. I requested them to inspect all the fabric rolls before delivery. Usually, they only perform random checks themselves. But if requested, they usually agree to full inspection. We either let them inspect and report to us, or showed up on-site during the inspection. If defects were found, they contacted me to confirm whether we could accept or replace the roll. Some suppliers, especially for larger orders, don’t offer full inspections. In this case, we would need to consider using a third-party inspection service nearby (usually 15–20 RMB per roll). Also, no fabric is ever 100% perfect, there would be some fault like stains, as long as it is not much, it is within tolerance, but serious defects must be avoided.

Step 7: Consolidation and Shipment

We placed orders to several different suppliers. Once all were ready, I coordinated with each supplier to deliver their fabric to a designated location during a fixed time slot. I went there to check and confirm the quantities, supervised the consolidation, and delivered the goods to the warehouse. Then I arranged sea freight and tracked the shipment until it arrived in the client’s country. I kept the client updated throughout from sourcing to delivery.

Final Thoughts

Behind what seems like a simple sourcing task, there’s often a lot of coordination, decision-making, and detail work. It’s not just about “buying fabric”. It’s about getting the right fabric, in the right quantity, at the right time, and making sure the client doesn’t face surprises down the line. Every step I took was reported to the client. Always give them solution, what my clients need to do is make the choice and decision.

Also, it is about trust. At the beginning, since this was our first time working together, the client asked about signing a contract. I actually drafted one, but they didn’t follow up. Instead, they chose to trust me and proceeded directly with the payment. I truly appreciate that, and I never take that kind of trust lightly.

I know that working with someone overseas, especially for the first time, takes a lot of trust. That’s why I always keep my clients informed, stay transparent, and treat their orders as if they were my own.

If you need help sourcing from China, fabrics or other products, you don’t have to be here in person. You don’t need to talk to 30+ suppliers. You just need someone who follows up, communicates clearly, and takes care of everything on the ground. I’m happy to help. (Contact Now)