Are you an independent designer, a startup fashion brand, or an e-commerce entrepreneur looking to launch your own clothing line? If so, you’ve likely encountered one of the biggest challenges in the process, finding the right production partner.

Many new brands struggle with balancing cost-efficiency, flexibility, and reliability in manufacturing. Most factories prioritize large orders because high-volume production is more profitable for them. But as a new or emerging brand, ordering large quantities upfront carries high financial risks, including high upfront costs, excess inventory and cash flow constraints.

You may have already reached out to factories that claim to accept small orders, only to experience:

- Slow response times

- Lack of priority treatment

- Quality issues that don’t meet your expectations

Why Do Most Factories Prefer Large Orders?

If you’ve reached out to manufacturers, you may have noticed that many either reject small orders or don’t prioritize them. Why?

The answer is simple: cost and time efficiency.

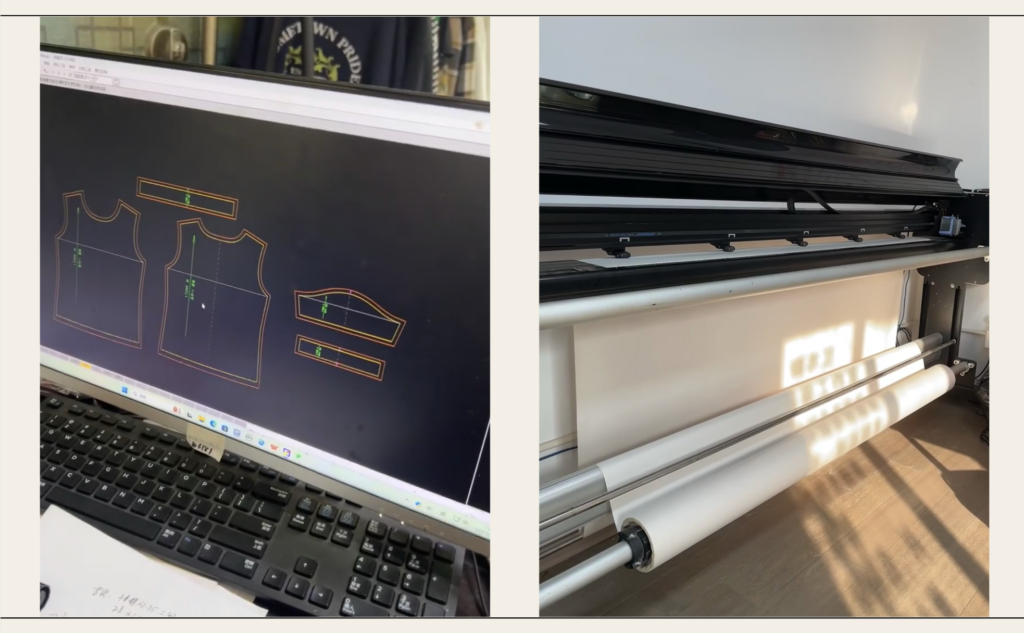

Clothing production is a complex process that involves multiple stages, regardless of the order size. Whether you are producing 10 pieces or 1,000 pieces, many of the steps remain the same:

- Fabric sourcing

- Pattern making & sample development

- Sample fitting & alterations

- Bulk fabric and accessories purchasing

- Bulk fabric inspection

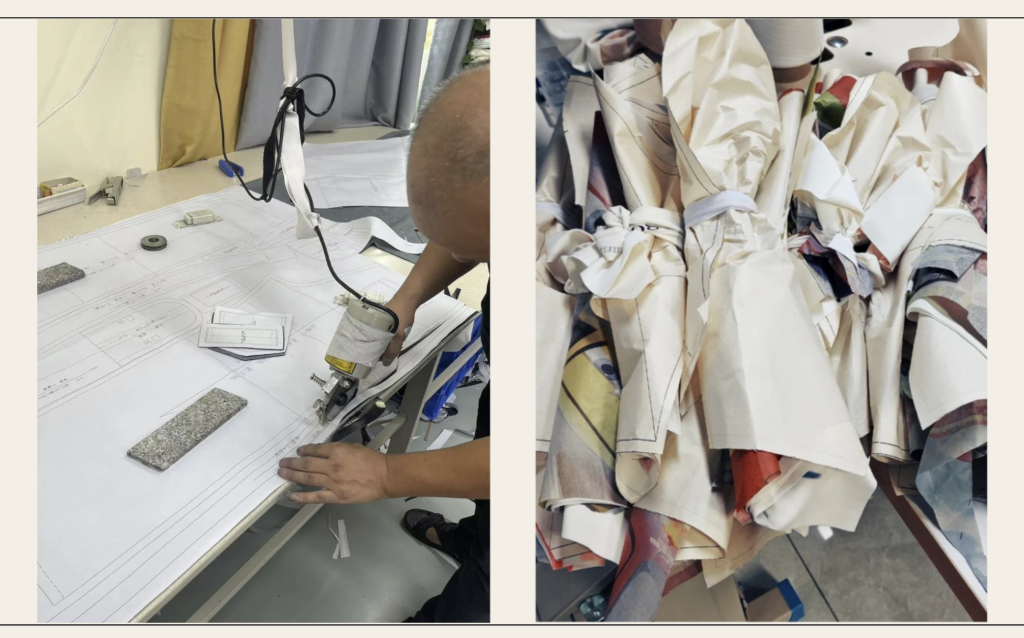

- Cutting & sewing

- Quality control

- Pressing & packaging

- More…

These steps require time, labor, and setup costs, which remain nearly the same regardless of order size. The difference? When you produce in bulk, these costs are distributed across more pieces, lowering the cost per unit.

- Large orders = Costs spread across more units = Lower cost per piece

- Small orders = Same effort, fewer units = Higher cost per piece

That’s why most factories prioritize large orders. They are simply more profitable.

While this can be frustrating for small brands, the fashion industry is changing. The rise of e-commerce, direct-to-consumer brands, and independent fashion labels has created a growing demand for small-batch production.

So, is small-batch manufacturing possible?

Absolutely!

You just need the right approach.

A Flexible Production Solution for Small Brands

A common misconception is that a single factory handles everything from start to finish. The truth is, clothing production is a highly segmented process, and factories rarely handle every stage themselves, which helps to lower the cost and more effectively.

In China’s well-developed garment supply chain, different specialized workshops manage different stages of production. This modular system allows for greater flexibility, making small-batch production more feasible.

For instance:

- Sampling studios – Focused solely on creating patterns and sewing samples.

- Fabric cutting teams – Dedicated to bulk fabric cutting.

- Small sewing workshops – Handle stitching and assembling garments. Most of them are consist of 1 couples or 5-6 machinists.

- Printing or embroidery houses – Specialize in custom embellishments, printing or embroidery only.

- Finishing workshops – Responsible for details like button holes creating and button attachment.

Unlike large factories where workers simply follow instructions, these independent workshops are often run by experienced professionals. Since their reputation depends on quality, they pay more attention to details and care about their work.

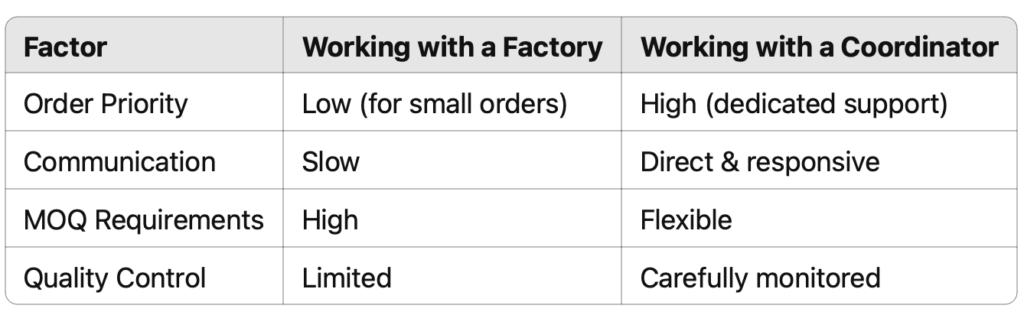

You Don’t Need a Factory—You Need a Coordinator

Instead of searching for a single factory that does everything (which is often costly and inefficient for small orders), you only need one coordinator to manage the process for you.

A production coordinator can help you:

- Source fabric and trims that match your design and budget.

- Work with a sampling studio to develop patterns and create samples.

- Order fabrics and trims for production.

- Coordinate production steps: cutting, sewing, printing, and finishing.

- Conduct quality control checks to meet your standards.

- With this approach, you can test designs, control costs, and refine your brand identity before scaling up.

It is something like you “own” a factory, you gain more control, flexibility, and visibility over the process.

Want to Bring Your Designs to Life? Let’s Talk!

Starting your own clothing brand doesn’t have to be overwhelming, and you don’t need a factory or a massive investment to get started. You just need the right production partner who understands your needs and can coordinate every step for you.

If you’re looking for:

- ✔ Small-batch production with flexible MOQs

- ✔ Reliable sourcing and manufacturing partner

- ✔ A hands-on production coordinator to oversee quality and delivery

Contact me today and let’s discuss how I can support your brand’s production journey!