Table Of Contents

Today, I’ll take you through new sample development process. This article is for designers, brand owners, and anyone interested in how to effectively collaborate with a factory to bring your clothing designs to life.

1. Receiving New Sample Request From Clients:

When received new sample request from clients, the tech pack is handed over to the sampling team. The tech pack includes detailed design sketches, measurement charts, and other necessary information and requirement.

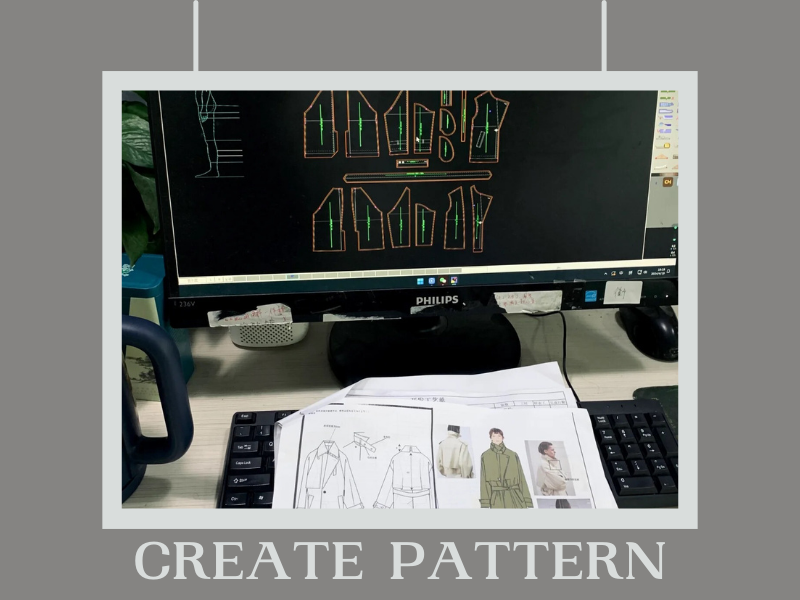

2. Creating the Pattern:

The pattern maker starts working on the pattern based on the tech pack. If any issues arise during the process, the pattern maker will flag them up and communicate to ensure every detail is accurate.

3. Fabric and Trims Sourcing and Preparing:

If the client has already chosen specific fabrics and trims, the factory will proceed to purchase them. If the client hasn’t selected fabrics and trims yet, the factory will source fabrics and trims based on the tech pack requirements and present them to the client for approval.

4. Sewing the Sample

Once all the preparations are complete, the factory begins sewing the sample. This step involves turning the pattern into a physical garment sample.

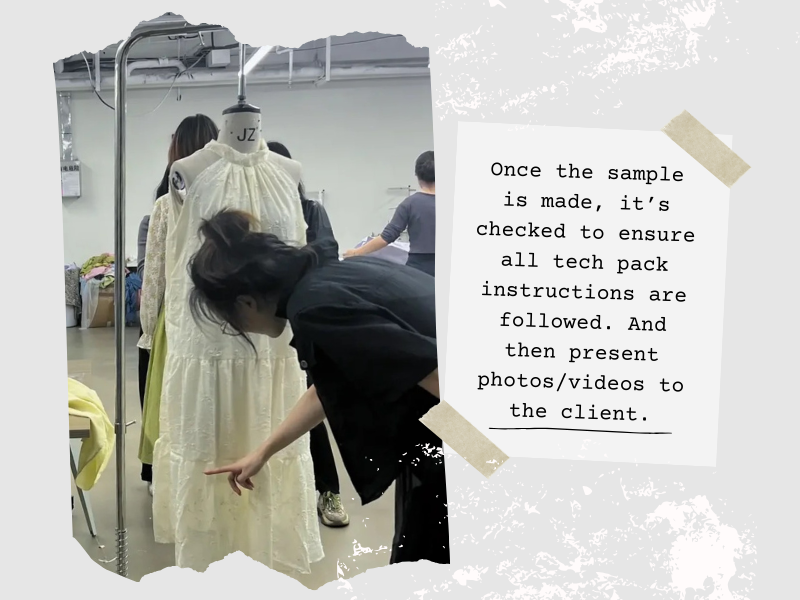

5. Checking and Taking Photos/ Videos:

When the sample is made, it is checked to ensure all instructions in the tech pack have been followed correctly. The sample is then put on a mannequin, and pictures or videos are taken and shown to the client.

6. Client Feedback and Minor Amendments:

Before shipping the sample to the client, it can be slightly amended based on the client’s comments.

Sampling Lead Time:

The sampling process typically takes 3 to 15 days, depending on the complexity of the sample and fabric/trims availability. For example, some fabrics need to be custom-made, which usually takes an additional 7 to 10 days, or more. If technique like printing or embroidery are involved, it may add another 3 to 5 days.

Tips: Double-check with your supplier ahead of time and consider these timelines when setting your deadlines.

Reducing Lead Time with Sample Blocks:

If the client provides a sample block to follow, it can speed up the process.

If there is no sample block, providing some inspiration images for reference is helpful.

I hope this above was helpful for you. By understanding the process and knowing what information is needed, you can work with factories more effectively.

Ready to bring your designs to life? Partner with us for seamless garment production! Contact for inquiries.